Camaro Chassis Structure Parts:

The stiffer a chassis structure, the more likely the vehicle is to have an even weight distribution on the tires which is favorable to acceleration and cornering. The chassis can twist under engine load during acceleration, vehicle cornering and maneuvering.

Straight line acceleration common with drag racing, can result in a twist in the vehicle chassis in the opposite rotational direction from the engine's crankshaft rotation (for every action, there is an equal and opposite reaction). A rigid chassis will resist this rotation by transferring the load directly to the tires while a chassis undergoing twist will build up the torsional load like a spring and release it leading to unpredictable behavior of the vehicle and making the vehicle harder to control. This twist can also reduce the effectiveness of the front tires used for steering the vehicle as one of the tires may lift off the ground, or at a minimum, be unloaded, reducing its effectiveness. In extreme cases, the vehicle twist will change the mechanical alignment of the engine , transmission, driveshaft and differential to such an extent that it will cause damage to the drivetrain and mounts. Acceleration in corners leading to vehicle twist will make the vehicle unruly and difficult to control accurately. Cornering and maneuvering can also twist the chassis resulting in uneven tire loading, also leading to poor vehicle control. A twisting chassis can also change your suspension geometry adversely changing the tire contact pattern reducing traction. Improving the rigidity of the chassis is an optimization between weight and stiffness.

| Jegs 762 Bonham Ave. Columbus, Ohio 43211 (800)345-4545 Part #: 550 40053 |  '82-'92 Camaro/Firebird bolt-in sub-frame connectors. Part #: 40053 |

Subframe Connectors: help reduce automobile body twist. Other sub-frame connectors from other manufacturers are not even close to this superior JEGS design. While it is marketed as a bolt-in, I recommend welding the unit. This unit is formed to fit tightly to the floor pan without protruding to reduce ground clearance. It bolts to the front of the rear trailing arm and is bolted (or welded) to the floor pan at the front. I also tack welded the sub-frame connectors along the chassis to spread load and increase chassis stiffness.

The purpose of the sub-frame connector is to stiffen the chassis. A torsionally stiff chassis will keep a more even load on all wheels to improve traction.

|

Steering Brace:

A stock GM brace used in some of the later Camaros was used here to add stiffness.

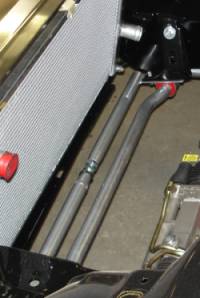

GM part # S14079634 connects between the two front frame rails and mounts above the front sway bar. It adds substantial stiffness needed in cornering and handling.

The load is generated by the steering gear which tends to flex an individual rail under hard cornering.

The brace causes both rails to share the load by connecting the two structures.

Aftermarket braces are also available.

The unit at the right is an adjustable aftermarket unit. |

|

Strut Tower Brace: Typically only used in the later model Camaro 3rd gen vehicles with fuel injection, this brace attaches to the top of the front shock absorber mount points. This helps maintain front-end suspension geometry maintaining the intended tire contact pattern with the road. The brace will attach them to each other and a third point, typically at the base of the windshield. This adds front-end rigidity by preventing the front chassis rails from twisting which maintains front-end wheel camber.

Manufacturer Links:

Jegs: Subframe connectors

Jegs: Subframe connectors

Spohn:

Spohn:

MAC: Strut tower brace (2 point attachment)

MAC: Strut tower brace (2 point attachment)

SSM: (Southside Machine) Subframe connectors

SSM: (Southside Machine) Subframe connectors

259 E. Main Street, Smithville Ohio 44677 (216)669-3556 BMR Suspension

BMR Suspension

- Pulley Engineering: Subframe kits, subframe connectors, roll bars and cages. (Drag racing)

Highway 64 East P.O. Box 212, McCrory Arkansas 72101 (501)731-2468