Camaro Fuel Systems:

The fuel system starts with the fuel tank. Fuel is either sucked out of the tank or pushed out with either an electrical or mechanical engine driven fuel pump. Fuel is delivered to a carburetor or fuel injection system which atomizes the fuel and delivers an air-fuel mixture to the engine to burn and develop power. Performance enhancements are available for the fuel pump and tank.

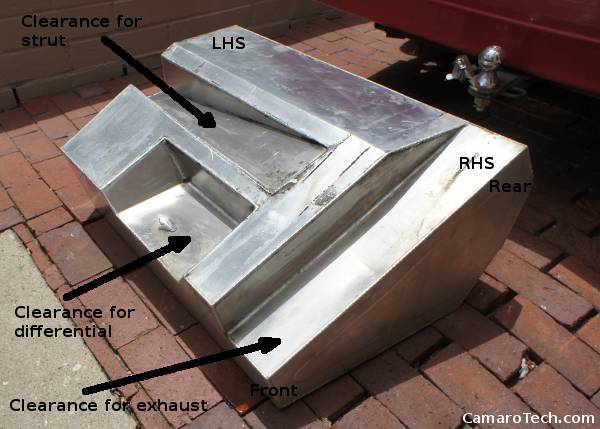

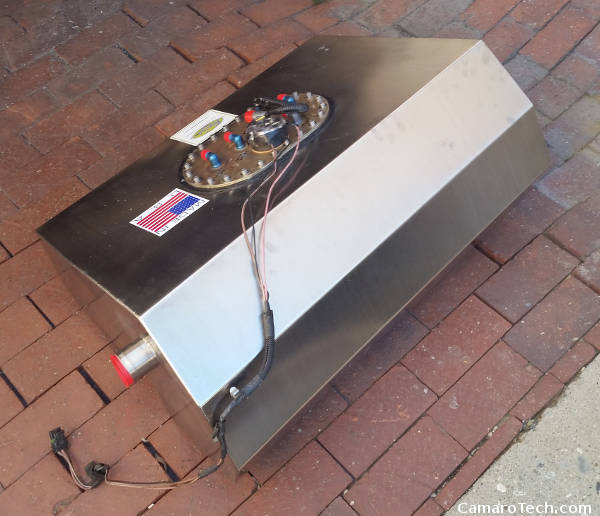

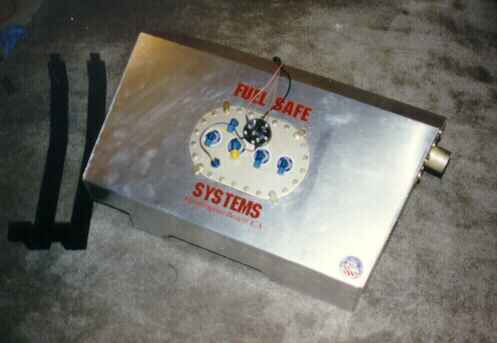

Fuel Tank: The stock Camaro fuel tank is too small for high horsepower engines when used for driving long distances. Racing fuel cells are typically too small for street driving. We show an installation for a Fuel Safe bladder lined, foam filled racing fuel cell for the third generation Camaro which supports the needs of both racer and street driver. We also show an installation of a high capacity street tank. These two tanks increase capacity to 24 gallons and improves crash safety. The tanks are custom designs for the 1982-1992 third gen Camaro and install in the stock fuel tank location.

The racing fuel cell has a nylon reinforced bladder lining to offer puncture protection to the thin aluminum fuel tank. The foam is designed to reduce the movement of the fuel. In the event of an explosion, the foam reduces flame propogation and the air volume in the cell. If the fuel cell does ignite internally, the foam absorbs the expansion and the energy of the explosion. According to racing fuel cell manufacturer, Fuel Safe, the cell must be filled with at least 80% foam to perform effectively and the foam only requires 3% of your tank capacity.

Note that all tanks should be grounded to avoid a static sparks. The movement of fuel in the tank and through the hose during re-fueling, can generate a static build-up.

Fuel Pumps: The CamaroTech project car used a GM submersible 1989 Corvette fuel pump (#25163463), an in tank fuel strainer (#25055458) and pressure regulator (#10185094) provided with the GM/3rd Gen Camaro ZZ3 engine swap kit. See the CamaroTech ZZ3 third gen installation.

The advantage of the submersible fuel pump is that it is at the beginning of the fuel delivery system thus pushing fuel and allowing the entire system to be pressurized. Older systems often had a mechanical pump on the engine sucking fuel, drawing fuel to the engine under low pressure. The advantage of a fuel system under pressure is that it reduces the chance for vapor lock, a condition where a fuel vapor bubble forms in the fuel line, blocking delivery of fuel and stalling the engine.

Performance fuel pumps are often required when an engine is upgraded in horsepower requiring additional fuel above and beyond its stock predecessor. Under high RPM and peak horsepower conditions, the engine may require a performance fuel pump to deliver the additional quantity of fuel required.

Fuel pressure gauges are often added to performance vehicles to verify a minimum fuel delivery pressure to achieve full engine horsepower potential.

Also see the GM ZZ3 engine kit installation which includes a conversion to a submersible electric pump.

| Aircraft Rubber MFG., Inc Fuel Safe Cell Div. [Part # SA114] 1550 NE Kingwood Ave. Redmond, OR 97756 (800)433-6524 (541)923-6005 24 gallon tank |

Camaro Fuel Bladder and Aluminum tank (available black powder coated) for a third generation Camaro. (Weight: 25.35 lbs. - without top plate, sender, etc. Stock tank weight without pump, sender and top plate: 21.4 lbs)

Installation Notes:Fuel tank support strut:

Note: The kit comes with a spacer to lower the support strut to allow for the extra size of the tank. I found it necessary to cut the support strut (and reinforce) due to the incorrect location of the valley in the tank. Attach with 3 bolts of M10-1.5x30mm.

Heat shields:The stock GM fuel tank installation used a heat shield to isolate the tank from the muffler/exhaust system. I chose to bend this shield so that it was included in this installation.

Fuel Lines and Fuel Pump:This project was part of the Chevrolet ZZ3 engine swap for the Gen 3 Camaro. This GM kit included a submersible Corvette electric fuel pump. This assembly was attached to the end of the pickup hose.Fuel Safe provides a marine fuel level gauge which you have to calibrate before installing. The attachments on the top plate are:

The fuel level sensing unit is manufactured by Centroid Products Inc and comes with the Fuel Safe tank. It is compatible with the GM Camaro fuel gauge and ranges from 0 ohms (empty) to 90 ohms (full) in resistance. The fuel level sender has three electrical connectors:

Filler Tube:I had to cut off the stock filler tube and weld it to a pipe which fit the rubber hose provided by Fuel Safe. The vent fitting was also welded to the tube.

Bladder Lifespan:The bladder must be changed every 5 to 6 years as the rubber will decay.

|

|

Filler Neck Supply:

Hose reducers |

Yup this company specializes in fuel filler necks. Really. Thankfully they had a 2-1/4" to 2" Fuel Fill Hose I.D. Reducer.

|

|

Rick's Tanks: custom tank:

San Antonio TX Stainless steel tanks. |

|

|

ATL Aero Tech Labs:

Reticulated Polyester Polyurethane Foam |

Foam baffles to prevent sloshing and weight transfer of fuel in corners. 12" x 6" x 24"

|

AEM Performance Electronics:

|

Machined from 6061 Aluminum, double Viton O-ring seals, 7 micron filter, 12 gpm@ 45 PSI. Uses replaceable filter cartridges. |

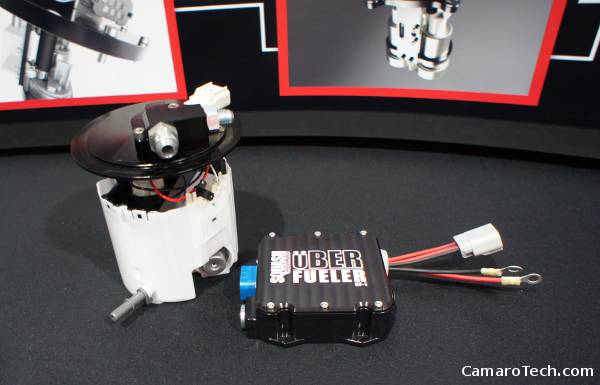

| Squash Performance:

(262)724-8035 Gen 5 Camaro 2010+ |

OEM replacement submersible in-tank dual electric fuel pump with a pre-programmed Uber Fueler electronic control. Plug and play wiring harness. Works with stock crossover tube and level sensor. |

| FueLab:

Litchfield IL 800-541-2345 |

Digital brushless fuel pump and digital regulator. Fuel regulator communicates with fuel pump digitally to avoid over-pumping and unnecessarily circulating and heating fuel. |

Links:

- Fuel Tanks:

- ATL Fuel cells

Fuel Safe [Catalog: see page 18] - Camaro tank SA114

Fuel Safe [Catalog: see page 18] - Camaro tank SA114

- Rick's Stainless Tanks: 1967-1973 Stainless steel Camaro gas tanks

- JAZ: Fuel cells

- RJS: Fuel cells

- Fuel Pumps:

- AeroMotive: for 250-2000 HP

- Barry Grant - high flow pumps

- Federal-Mogul: Carter fuel pumps

- Federal-Mogul: Carter: electric OEM replacement, hi-performance and accessories (wire harnesses, strainers, tank lock rings, ...)

- Edelbrock: Mechanical, electric, submersible, regulators

- FueLab: digital fuel pump and regulator

- Holley: Mechanical, electric in-line and in-tank, pressure regulators, ...

- MagnaFuel: electric pumps (for Carbureted and EFI engines), regulators and filters

- Mallory: Mechanical, electric in-line, and in-tank, fuel rail EFI, regulators, fuel lines, fuel gauges, fittings, filters

- Paxton: pumps, regulators, filters, FCU, ...

- Fuel Lines and Fittings:

- Edelbrock: Russell: stainless steel hose ends, braided lines and fittings

- Eaton: Aeroquip: stainless steel braided racing hose, fittings (AN and metric), crimping tools, aluminum fittings, ...

- Spectre: hose and sleeve kits, filters

- Holley: Earl's: braided stainless steel hose and fittings

- Classic Tube

- Godman Hi-Performance - fuel line components, fuel specific gravity measurement kits, adapters, etc

- Filler Neck Supply: They specialize in filler necks, caps, diameter changes, etc

- Fire Suppression:

- Stroud - Halon fire suppression

- Deist

- Firefox

- SPA - SPA FIA approved systems

- Accessories:

- Lokar: carb linkage

- FRAM: filters

- Auto Meter: Fuel Gauges

- Stewart Warner: Fuel Gauges

- VDO: Fuel Gauges, automotive electronics

- AEM Performance Electronics: High volume fuel filters, fuel rails, pressure regulators, water and methanol injection systems, gauges, sensors, fuel/ignition controllers, data loggers